About

- HOME >> About >> Quality Control

-

Key Aspects of Our Quality Control Process

At Upbright, quality control is the foundation of everything we do. Our commitment to providing high-quality products is reflected in our comprehensive Quality Control (QC) processes, which ensure that every batch meets the strictest industry standards for performance, consistency, and safety.

-

1. Raw Material Selection and Testing

- Sourcing from Trusted Suppliers: We carefully select raw materials from verified, high-quality suppliers to ensure that the base ingredients meet our stringent quality standards.

- Incoming Material Inspection: All raw materials undergo thorough testing before they are approved for production. This includes testing for purity, consistency, and chemical composition to ensure that only high-quality materials are used.

- Chemical Analysis: We conduct detailed chemical composition tests on raw materials to ensure that they meet the required specifications and regulatory standards, such as REACH and RoHS compliance.

-

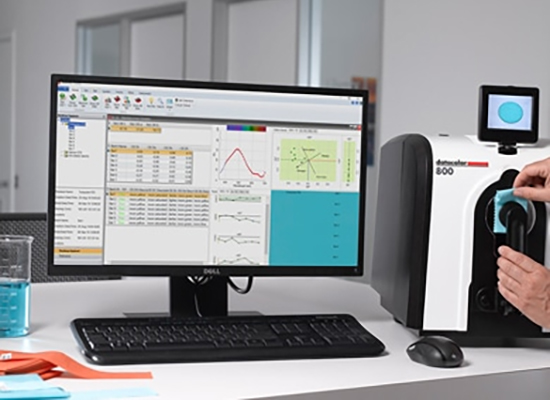

2. In-Process Quality Control

- Real-Time Monitoring: Our production facilities are equipped with advanced monitoring systems to oversee key manufacturing processes. This ensures consistency in temperature, mixing, and other critical parameters that affect dye quality.

- Process Sampling: Samples are taken at various stages of production to check for consistency in color, solubility, and other performance metrics. This ensures that the batch meets our quality benchmarks before moving forward.

- Process Optimization: Our experienced technicians continuously optimize production conditions to maximize product quality while minimizing waste and variability.

-

3. Final Product Testing

- Batch Testing: Once production is complete, each batch undergoes rigorous testing in our in-house labs. We assess key properties such as:

- Color Consistency: Ensuring the shade is vibrant and matches the required specification.

- Solubility: Verifying that the dye dissolves uniformly in specific organic solvents.

- Heat Stability: Testing the dye's resistance to high temperatures, critical for applications in plastics and coatings.

- Lightfastness: Evaluating the dye’s ability to resist fading when exposed to light, especially for outdoor and automotive applications.

- Chemical Resistance: Testing for resistance to solvents, acids, and other chemicals based on the intended application.

- Performance Testing: We conduct performance tests under various environmental conditions to ensure the dye can withstand real-world application stresses such as heat, light, and chemical exposure.

-

4. Certification and Compliance

- Regulatory Testing: All products are tested to ensure compliance with international regulatory standards, including REACH, RoHS, AP89-1,EN71-3,FDA

OEKO-TEX Standard 100,ISO9001....- Documentation: Each batch is accompanied by Certificates of Analysis (COA), ensuring that customers receive detailed information about the batch’s specifications and quality.

Leave your message.

-

Location

Sales office: Yinzhou,Ningbo,Zhejiang

Factory address: Xiaoshan,Hangzhou,Zhejiang